0592-5758917

Download

Solution

About us

Understand the latest technical information

Please enter the download center

Products

News

Contact

Service Hotline

Page copyright © 2018 Winservo (Xiamen) Electrical Technology Co., Ltd. 闽ICP备2021015213号-1 Website construction:300.cn

SOLUTION

Faucet screwing machine

The application of the common blob servo on the self locking joint of copper pipe

Industry background (industry application field)

Copper water pipe is a kind of copper tube. It is made of high quality copper. The copper pipe and fittings are the best choice for water supply, gas supply and heating piping system. They can be widely applied in building cold, hot water supply and drainage, direct drinking water, reclaimed water, gas, medical, food, chemical and other fields.

The copper water pipe joints were all artificially screwed up before, and the efficiency is low. So the Yong Bo servo motor is used to output the precise torque at high speed, and the customer only needs to set the torque on the screen, so the servo will lock the joint to the corresponding torque.

Two. System scheme

Comparison of 1. schemes

2. customer demand

3. solution

4. system program flow chart:

4. system characteristics

Before the manual tightening, skilled workers a person an hour wring 200, now using the servo scheme, one hour can be screwed 500~600, efficiency increased by 300%.

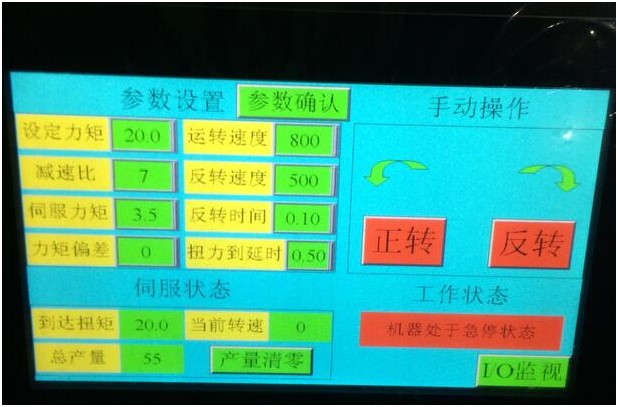

The touch screen is easy to operate, and the locking degree of the self locking joint of the copper pipe can be set by the screen.

Three. System hardware design

1. hardware list

2. mechanical structure

It is composed of a copper pipe head fixed frame, the copper pipe male head rotating frame, close to the switch induction product, the operation interface and so on.

3. electrical aspects

4. software design

4.1 process flow

The first public copper pipe head on the fixed rotating zone, copper pipes male head start rotating at set speed, the copper pipe female head arranged on a fixed frame, under pressure to contact with the copper pipe head, began locking, when the torque value set, stop lock, motor reversal will be finished to rotate in order to take position.

4.2 control process

4.3 parameter setting

4.4 wiring

4.5 program display

Four. Summary of the project

The preliminary plan is very important to choose to start with speed mode, due to inertia, will cause the product tightness error 6~10N, through continuous experiments it is found that the torque model is more suitable for the equipment, and to set the torque should delay some time to reverse the best products. The operation of the Yong Bo servo touch screen is simple. The locking degree of the self locking joint of the copper pipe can be set by the screen. It can achieve an 500~600 of one hour, and the efficiency is increased by 300%.