0592-5758917

Download

Solution

About us

Understand the latest technical information

Please enter the download center

Products

News

Contact

Service Hotline

Page copyright © 2018 Winservo (Xiamen) Electrical Technology Co., Ltd. 闽ICP备2021015213号-1 Website construction:300.cn

SOLUTION

Warp knitting machine

First. Introduction

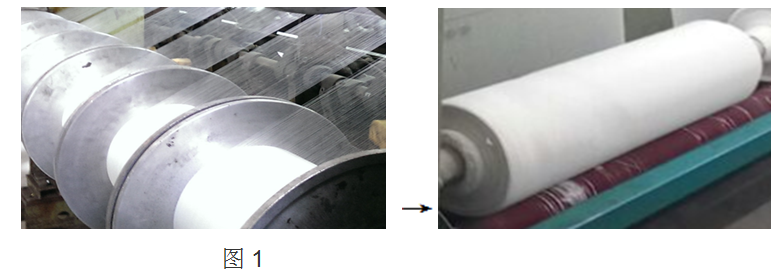

A group or groups of parallel yarns are knitted together on all the working needles feeding to the machine at the same time. This method is called warp knitting, and the fabric is called warp knitted fabric. The machine that completes the warp knitting is called the warp knitting machine. (Figure 1 is a physical display)

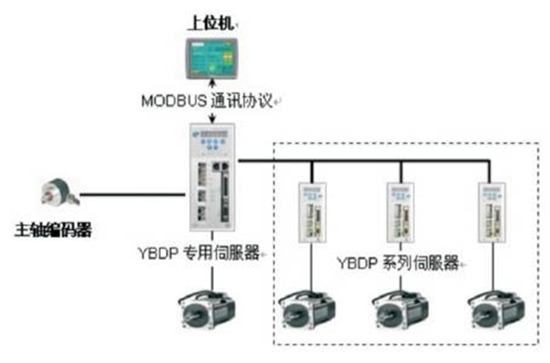

Winservo textile special server replaced the early low quality mechanical delivery and solved the common malfunction of early mechanical equipment and expensive maintenance. Yong Bo textile special server with intelligent electronic let off system, and can realize man-machine interface direct communication parameters setting sand feed and read, the system satisfies the conditions of the textile in the high-speed dynamic detection of sand tension, detect the signal and signal setting calculation and comparison, and sent by the take-up control and adjustment. To effectively improve the fabric quality, suitable for all kinds of shuttleless loom electronic let off and take-up motions, main drive and machine coiling equipment. (the following diagram is a mediocre electronic delivery servo system structure)

Winservo scene display (picture for the application of servo Longsheng textile factory shooting)

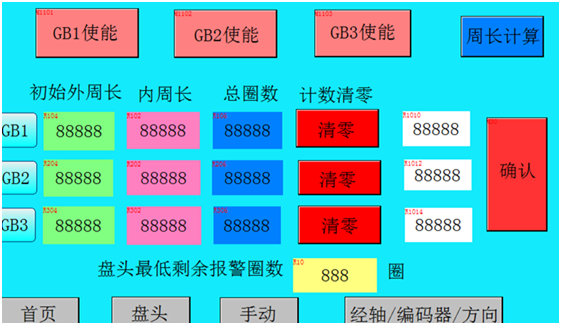

Touch screen excerpt 2

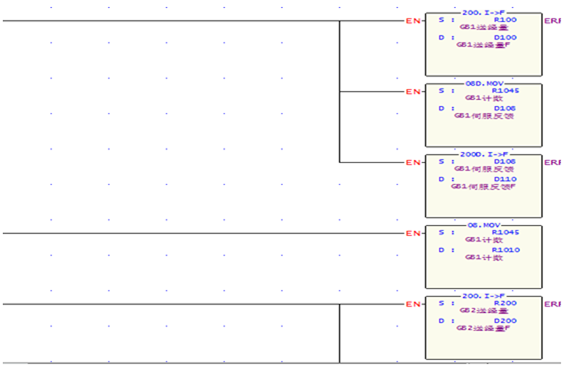

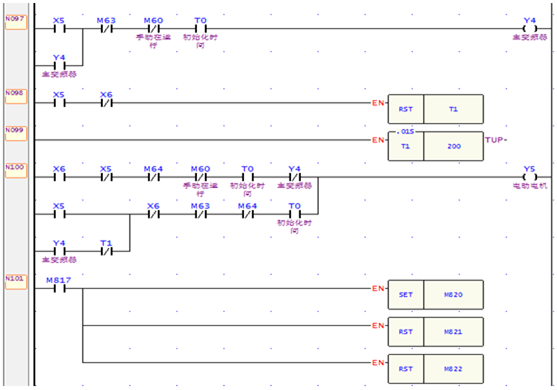

PLC program excerpt 1